| Hydro power plant solutions

Hydro power plant solutions

Currently, the use of the most advanced automation technologies to increase the reliability and availability of plants along with favorable hydrological conditions is the trend and demand of Hydropower plants. in Vietnam and around the world. For example, the addition and replacement of automation solutions for the plant has helped Hoa Binh hydropower (8×240 MW) achieve the highest annual power output ever. FRA company is a leading company providing solutions for hydropower plants including: SPEED – DIFFERENT – DCS

DocumentTypical features

I. SPECIFICATIONS

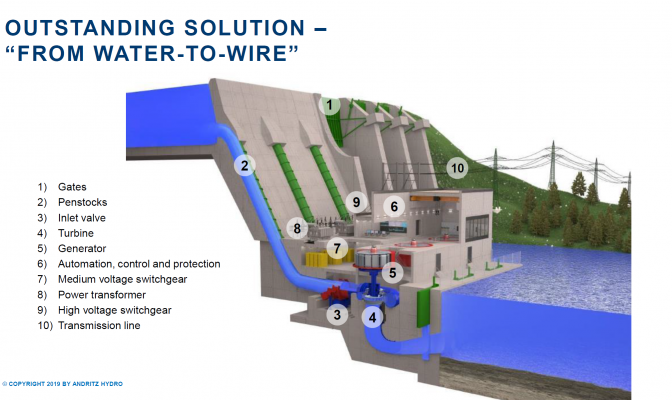

The speed control system is a system that automatically adjusts the speed of the unit to always at the rated value when the unit is in normal operating mode. At the same time, this system also needs to ensure the following functions: • Automatic or manual start of the unit. • Idling the unit. • Make sure the generating set works on the grid in the following modes: “Power”, “Frequency”, “Group control” and “Synchronous compensation”. • Make sure to convert the unit from power mode to compensation mode and vice versa. • Automatically switch from “power”, “group control” mode to “frequency” mode when the grid frequency exceeds the allowed value. • Stop the unit in compensation mode. • Normal stop and unit breakdown stop. With the speed control solution for hydroelectric power plants, ANDRITZ Hydro has been selected by FRA as a strategic partner, providing products for this solution in the Vietnamese market. ANDRITZ Hydro is a member of ANDRITZ International Technology Group. ANDRITZ Hydro is the world’s leading supplier of synchronous electromechanical equipment systems and complete engineering services (“from water-to-wire”) for hydroelectric projects. Moreover, the company is also a market leader in the field of modernization, renovation and equipment upgrading of hydroelectric power plants that have been in operation for many years. Combining Andritz’s leading technology and experience in the field of hydroelectric power plants and FRA’s dedicated and professional engineering team, FRA offers the ultimate solution for supply, renovation, upgrading, optimize the speed regulation, excitation and DCS systems of hydroelectric power plants.

II. SIZE

The basic function of the excitation system is to provide direct current to the field winding of the generator. The excitation system is controlled and protected to meet the reactive power of the system; through voltage control by field current control. With the requirements of the excitation system mentioned above, currently FRA cooperates with ANDRITZ Hydro to bring the best quality solution for hydroelectric power plants in the country. The most commonly used excitation systems include the following: • One-way excitation system; This system uses a DC generator that supplies current to the field windings in the rotor of the synchronous generator through slip rings and brushes. • Alternating excitation system; This system usually uses an AC generator as the excitation power source of the main generator. This system is also known as brushless excitation system. • Static excitation system: The field coil is supplied with a controlled rectifier or a non-controlled rectifier. For the system using thyristor rectifier called excitation system

III. DCS FOR HYDROPOWER FACTORY

DCS system of Hydropower Plant is a system that integrates all information of the Plant including from technological equipment, energy, electrical equipment, output substation and ancillary systems for monitoring work. factory monitoring and control. With the requirements of the above DSC system, currently FRA cooperates with ANDRITZ Hydro to bring the best quality solution for hydroelectric plants in the country.

OUR PROJECTi

View Project